When your Allison transmission starts to act up, finding reliable information is crucial. In this Allison transmission troubleshooting guide, we’ll arm you with knowledge to pinpoint and manage typical malfunctions.

Expect clear advice on error codes, maintenance tips to avoid common pitfalls, and signs that it’s time to seek professional assistance—giving you the power to extend the life of your transmission.

Key Takeaways

- Regular maintenance of Allison transmissions, such as fluid and filter changes, is critical for preventing common problems and ensuring the longevity of the transmission system.

- Identifying and addressing symptoms of Allison transmission trouble early, such as harsh shifting or delayed engagement, can prevent costly repairs and maintain optimal performance.

- Professional assistance should be sought for complex issues beyond DIY repairs, with authorized service centers and warranty options providing reliable support for Allison transmission care.

Decoding Allison Transmission Issues

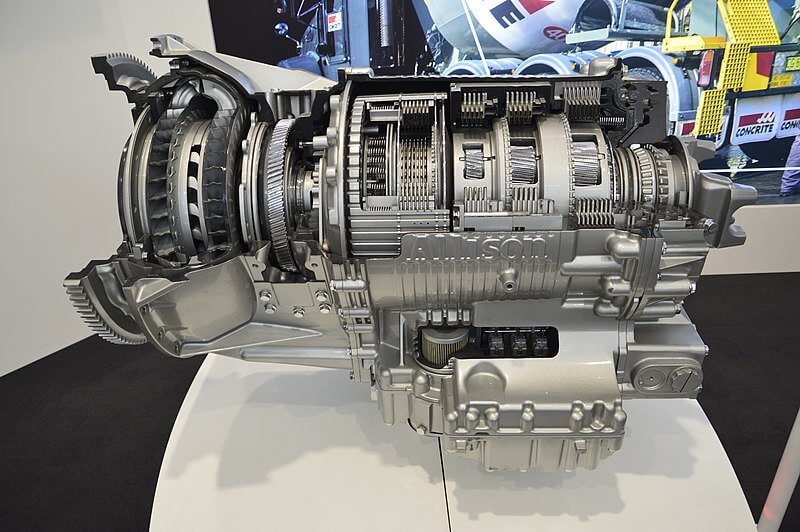

Like any mechanical component, Allison transmissions may encounter performance-affecting complications. Early detection of these common issues is crucial for avoiding system failure and maintaining the seamless functionality of your vehicle.

These common problems include part malfunction or activation of failsafe modes, hookup errors, especially in older units, along with other rectifiable concerns. Consistent maintenance is instrumental in resolving such issues early on to ensure that the transmission remains serviceable instead of requiring full replacement.

For over 100 years, Allison Transmission has established a reputation for durability and effectiveness across diverse applications. Understanding and identifying typical malfunctions can play an essential role in averting serious setbacks, thereby extending the service life of your Allison transmission system.

Identifying Symptoms of Transmission Trouble

Identifying early signs of transmission issues can help you avoid expensive repairs and unnecessary downtime. Harsh shifting is one such sign, evidenced by abrupt transitions between gears that may suggest impending transmission problems.

This could result from a variety of factors including inadequate or deteriorating transmission fluid, blocked filters, depleted clutch packs, or an impending problem with the clutch.

Likewise, if there’s a significant pause while switching your vehicle’s Allison transmission from park into drive or reverse gear — known as delayed engagement — it’s an unmistakable signal that your vehicle’s transmission needs immediate inspection.

Early detection and resolution of these symptoms are crucial for preserving the performance and longevity of your Allison gearbox.

Understanding the Role of the TCM Module

Allison transmissions heavily depend on the performance of the Transmission Control Module (TCM). It orchestrates the timing and application of gear changes to optimize vehicle performance and fuel efficiency.

However, it’s not immune to issues. In fact, in the mid-2000s, Allison transmissions faced a recall specifically targeting the TCM module due to a tcm module problem that impacted the transmission’s performance.

TCMs in first through third-generation Allison transmissions typically use three connectors, each consisting of 32 pins, to interface with the vehicle’s various systems and sensors.

Issues with the TCM in Gen 4 applications can present a range of symptoms and Diagnostic Trouble Codes (DTCs), indicating potential problems that need to be addressed. Understanding the role of the TCM and being able to identify issues can help maintain optimal performance of your Allison transmission.

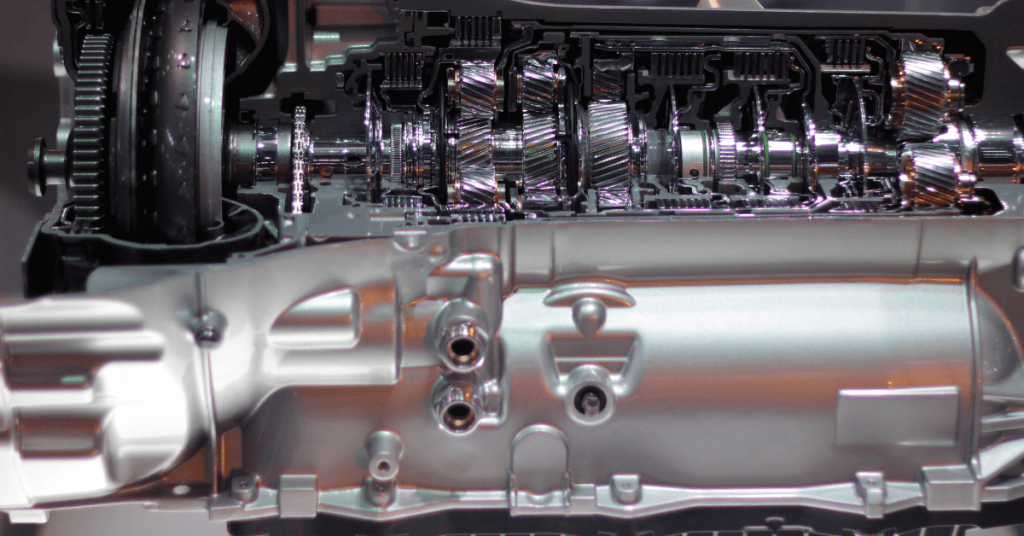

The Impact of Fluid Quality on Transmission Performance

The performance of your Allison transmission can be greatly affected by the quality of its fluid. Maintaining high-quality fluid is essential to avoid problems such as erratic shifting and burnt clutches. It’s important to use fluids that meet Allison’s TES-295 specifications, for example, Transynd, which provides enhanced protection under a range of driving conditions.

To keep your Allison transmission in top condition and eliminate contaminants like metal particles, regular maintenance is crucial. This includes changing the oil and replacing internal filters every 60,000 miles.

Adhering to these maintenance practices will substantially benefit both the performance and longevity of your Allison transmission.

Navigating Common Operational Faults

Even with their sturdy construction, Allison transmissions may still encounter functional issues. For example, the Allison 1000 transmission has been noted for its tendency to sporadically enter limp mode without warning, an issue often accompanied by diagnostic trouble codes P0670, P0700 and P1621.

When in limp mode, the system confines the transmission to operate in third gear only—a safeguard that allows a driver to continue driving at reduced functionality to a secure location or auto repair shop while mitigating potential harm from conditions such as overheating or hauling excessive weight.

One prevalent problem is gear slippage. This can be attributed to inadequate levels of transmission fluid, wear and tear on clutch plates or malfunctioning solenoid packs—all contributing factors that might cause gears within the transmission system to not remain engaged properly.

Common are various shifting complications and performance anomalies which have been reported, particularly among first through third-generation LCT1000s. Being aware of these frequent operational faults plays a crucial role in managing them effectively so as to maintain your Allison’s peak operating condition.

Solving the Limp Mode Conundrum

Limp mode is a protective feature designed to prevent further damage to the transmission when a problem is detected. It restricts the transmission to third gear, allowing the vehicle to be driven to a safe location or repair facility.

To resolve limp mode, follow these steps:

- Perform a diagnostic scan to identify and correct the fault causing the transmission to enter this protective state.

- Once the fault is identified, take the necessary steps to fix the issue.

- Regularly maintain your Allison transmission to ensure optimal performance and extend its lifespan.

By following these steps, you can effectively resolve limp mode and keep your transmission running smoothly.

Addressing Harsh Shifting and Slipping Gears

The smooth gear transitions and effective power transmission of Allison 10-speed transmissions have earned them a reputation for reliability.

Yet, it’s not rare to encounter complaints regarding abrupt shifts and gears that slip. Several causes like insufficient fluid levels, deteriorated clutch plates, or defective solenoid packs can lead to such problems.

Electrical complications may result in severe or incorrect shifts with your Allison transmission. Taking swift action to rectify these issues is crucial in preserving both the performance and durability of the transmission system.

Resolving Reverse Gear Failures

If the reverse gear does not engage, it is crucial to initially examine the NSBU switch for faults. Scrutinize both the valve body and output shaft of your Allison transmission as they can contribute to problems with engaging reverse.

Gaining insights into rectifying issues with reverse gear engagement is key in upholding your Allison transmission’s performance and averting expensive repairs.

Tackling Electrical and Sensor-Related Problems

Disparities in voltage and complications with grounded wires can significantly affect the function of Allison transmissions. Such electrical and sensor concerns may result in various transmission issues, particularly failures within the reverse gear.

It is crucial to be aware of these challenges and possess knowledge on how to address them effectively to ensure your Allison transmission operates at its best.

Wiring Harness Woes

Over time, especially in diesel vehicles that have covered a lot of ground, the Allison LCT1000 transmission units may face problems with electronic controls and the integrity of their wiring harnesses. Issues like an improperly fastened transmission plug could interfere with signals and control functions, prompting the transmission to switch into limp mode.

To avoid such disruptions and maintain optimal operation of your Allison Transmission, it is crucial to regularly inspect and maintain the condition of its wiring harness.

Output Speed Sensor Failures

If an output speed sensor within the Allison transmission is malfunctioning, it could lead to issues like harsh gear changes, a disabled cruise control system, and triggering the Check Engine warning. Defective speed sensors in the transmission might disable cruise control for safety reasons.

To replace a damaged output speed sensor, it may be necessary to extract the entire transmission from its place inside your vehicle. This can increase repair complexity significantly. Grasping these challenges and knowing how to effectively address them is crucial for preserving both performance and durability of your Allison transmission.

Preventive Measures and Maintenance Strategies

Ensuring the durability of your Allison transmission can be achieved through proactive maintenance and staying abreast of current Allison transmission advancements.

By preventing potential issues before they arise, such as routine servicing that includes replacing the spin-on filter every 30,000 miles and updating the internal filter between 50,000 to 100,000 miles, you contribute significantly to your Allison transmission’s well-being.

By implementing upgrades like a transmission cooler enhancement for your Allison unit may greatly improve its performance while prolonging its lifespan. Adopting these preventative steps and diligent upkeep routines will assist in maintaining seamless operation of your Allison transmission over an extended period.

Scheduled Maintenance: Your First Line of Defense

Regularly maintaining your Allison transmission is key to ensuring its dependability under typical operating conditions. By performing proper maintenance, you can help avert the unintended activation of limp mode in your Allison transmission.

Implementing scheduled or proper maintenance acts as a primary safeguard against potential problems, thereby extending the service life of an Allison transmission.

Keeping the Transmission Cool Under Heavy Load

Upgrading to a transmission cooler can greatly reduce the chances of your transmission overheating, an occurrence that is particularly likely when you are towing large weights.

It’s essential to keep an eye on the temperature of your transmission fluid if you want to preserve the condition and efficiency of both your torque converter and transmission during intense operations.

By opting for an Earl’s aftermarket transmission cooler, it is possible to substantially lower temperatures within the Allison Transmission while it bears heavy loads.

This addition helps maintain a steady operating range around 80-90 degrees Fahrenheit above the surrounding air temperature, even during towing tasks. Such cooling measures under burdensome conditions are key in boosting both performance and longevity of your Allison Transmission system.

When to Seek Professional Help

Recognizing when a transmission issue is beyond the realm of home repairs is crucial. Should straightforward troubleshooting methods not rectify the problem, it’s time to seek expert assistance. Take for instance an Allison 1000 transmission that gets stuck in limp mode and cannot be reversed manually – this scenario necessitates advanced diagnostic tools and professional know-how.

In situations where there are indications of a Transmission Control Module (TCM) malfunction, especially if it has never undergone replacement, consulting with the manufacturer for direction can prevent additional problems and safeguard your Allison transmission from Harm.

Authorized Service Centers: Ensuring Expert Care

Specialized care designed for Allison transmissions is available at authorized service centers, promoting proper operation and extending their lifespan. At these centers, qualified technicians possess the know-how to pinpoint and fix intricate problems, returning your Allison transmission to its peak performance.

With over 1400 distributors and dealers across the globe, including A-1 Transmission, Allison Transmission Specialists, at 2600 NE Hudson Rd Rogers, AR 72756, Allison Transmission ensures that you have access to seasoned professionals and efficient servicing options. This expert attention helps sustain your transmission’s performance and prolongs its durability.

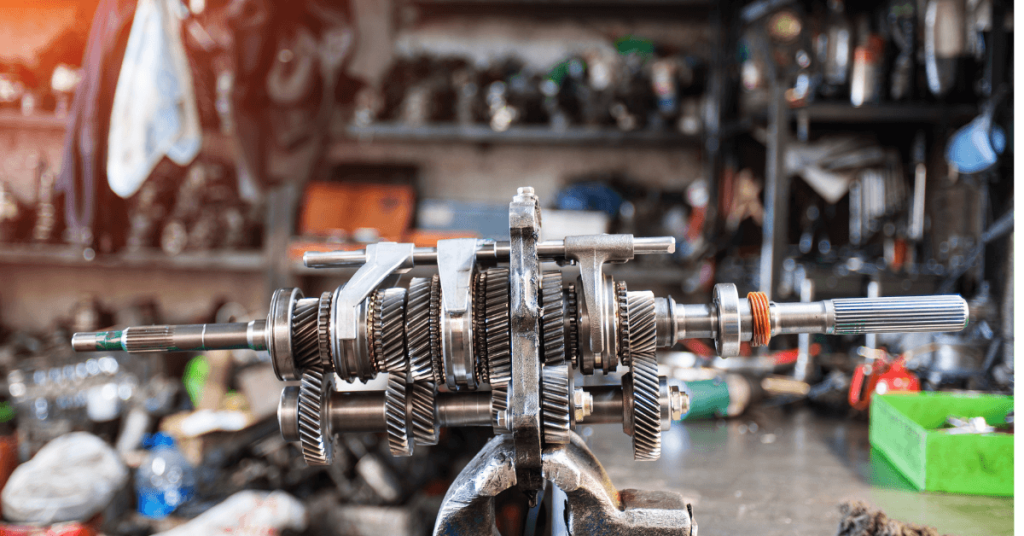

Warranty and Rebuild Options

Reconstructing an Allison transmission professionally offers the benefit of improved dependability and extended service life following the overhaul. Opting for a rebuild can be more cost-effective than investing in a new transmission or acquiring another vehicle.

A-1 Transmission stands out as one of the limited number of workshops endorsed to perform certified rebuilds on Allison transmissions, which signifies their adherence to stringent quality criteria.

Post-rebuild warranty services may apply to these transmissions, granting additional confidence and value to patrons. Being well-informed about your warranty choices and reconstruction alternatives is crucial when considering maintenance for your Allison transmission.

Summary

In summary, Allison transmissions stand as durable and effective mechanisms that have the potential to exhibit exceptional functionality when maintained correctly. Being cognizant of typical problems, remaining alert for signs of malfunctions, and committing to consistent maintenance can greatly prolong the durability of your transmission from Allison.

Recognizing when it’s necessary to consult experts and being informed about warranty coverage as well as reconstruction alternatives are crucial steps in avoiding expensive fixes and unnecessary operational breaks. Remember these recommendations to maximize the performance from your Allison Transmission system.

Frequently Asked Questions

What are the common problems with Allison transmissions?

Allison transmissions commonly experience issues such as harsh shifting, slipping gears, limp mode activation, and reverse gear failures. It’s important to address these problems promptly to avoid further damage or safety concerns.

What is the role of the Transmission Control Module (TCM)?

The TCM oversees the synchronization of gear shifts to improve the vehicle’s performance and optimize fuel economy.

What is limp mode in Allison transmissions?

When an issue arises, Allison transmissions are designed with a safety feature known as limp mode, which confines the gear to third gear. This safeguard is intended to prevent additional damage by locking the transmission in this specific gear.

How can I maintain the fluid quality in my Allison transmission?

To ensure the quality of fluid within your Allison transmission is preserved, it’s essential to periodically change the oil, swap out internal filters, and utilize fluids conforming to Allison’s TES-295 standards.

Adhering to these measures is vital for maintaining the peak performance and extending the life of your Allison transmission.

When should I seek professional help for my Allison transmission issues?

Should basic troubleshooting measures fail or if there’s a suspicion of a defective Transmission Control Module (TCM) that has yet to be replaced, consulting with an expert is advised for resolving issues concerning an Allison transmission.