The Electrical Diagnostic Process

Trained technicians follow a systematic process to locate issues quickly and accurately:

- Interview: The technician gets a full description from the owner on the symptoms, when issues occur, and any recent repairs. This provides clues to the problem.

- Visual Inspection: All electrical components are inspected for external damage, corrosion, loose wires or connectors, etc. Problems like damaged wiring can be found quickly.

- Verify Complaint: The tech test drives the vehicle and attempts to duplicate the issue. Intermittent problems are especially challenging.

- Check Service Bulletins: The make/model is checked for technical service bulletins related to known electrical issues. These point to likely culprits.

- diagnostic trouble codes (DTCs) that indicate issues in specific systems.

- Testing Circuits: Using wiring diagrams, each circuit related to the symptoms is systematically tested to isolate breaks, shorts, resistance problems and loose connections.

- Repair Verification: Once repairs are made, the system is retested thoroughly to ensure normal operation before returning the vehicle.

Advanced Diagnostic Tools

Electrical diagnostics requires high-tech equipment to test circuits, components and computer networks:

- Digital Multimeter: Tests voltage, resistance and amperage in electrical circuits and components. Critical for finding shorts, breaks, resistance faults and power issues.

- Lab Scope: Displays electrical signals in circuits on an oscilloscope to check sensor values and find irregularities.

- Scanner: Connects to vehicle computer networks to read sensor data, run tests, check for diagnostic trouble codes, and turn components on/off.

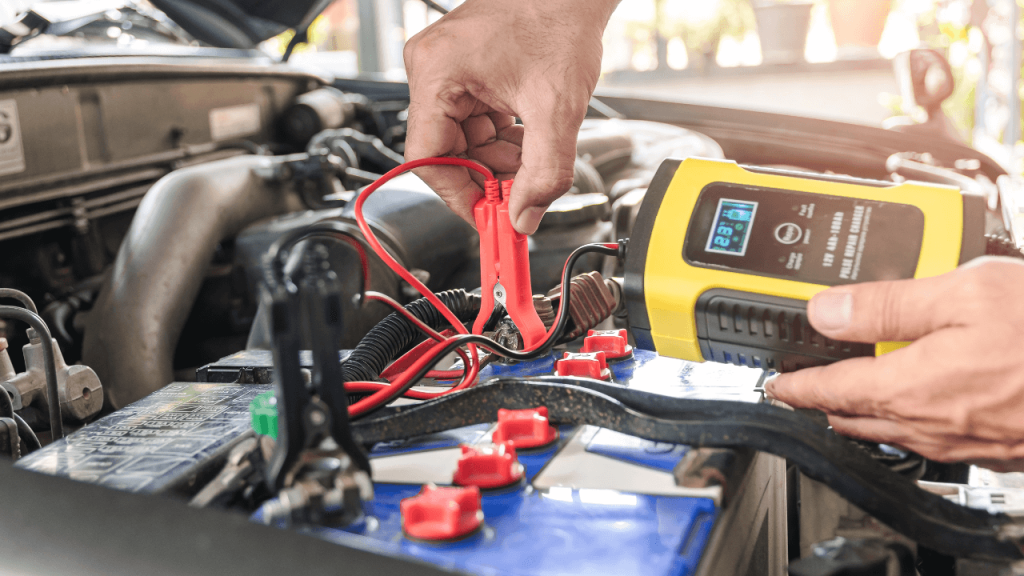

- Battery/Starting/Charging Tester: Tests battery health, starter draw and alternator output. Many no-start conditions stem from these components.

- Fuse Tester: Quickly finds blown fuses that disable electrical circuits.

- Wiring Diagrams: Show how circuits are designed to operate normally. Technicians analyze against actual readings to isolate malfunctions.

Benefits of Proper Electrical Diagnostics

Performing thorough diagnostics has many benefits:

- Saves money by avoiding unnecessary parts replacements when the root cause is uncertain.

- Avoids comebacks by identifying the actual fault so it can be repaired correctly the first time.

- Confirms safety components like airbags, ABS modules and stability control are operating properly.

- Fixes electrical issues before they leave drivers stranded.Optimizes vehicle performance, gas mileage and reliability by keeping electrical systems working as designed.

In summary, auto electrical diagnostics is a complex but systematic process enhanced through high-tech tools. Skilled technicians use specific diagnostic steps and equipment to hunt down electrical gremlins hidden within a vehicle’s intricate wiring and computer networks.

This allows the correct issue to be identified and fixed accurately and efficiently.