Over time, engine components wear down from the demanding stresses of combustion and operation. Rebuilding your engine restores optimal performance and longevity. Here’s what you need to know about the engine rebuilding process.

When Do You Need Engine Rebuilding?

Consider engine rebuilding services when your engine shows these signs:

- High mileage exceeding 100k-150k miles

- Loss of power

- Rough idle

- Reduced acceleration

- Oil burning smell from the exhaust

- Engine overheating

- Low oil pressure

- Knocking or rattling noises

Rebuilding is much cheaper than replacing the engine altogether. Technicians can identify worn parts and recondition or replace just what’s needed. This returns your engine to like-new condition.

The Engine Rebuilding Process

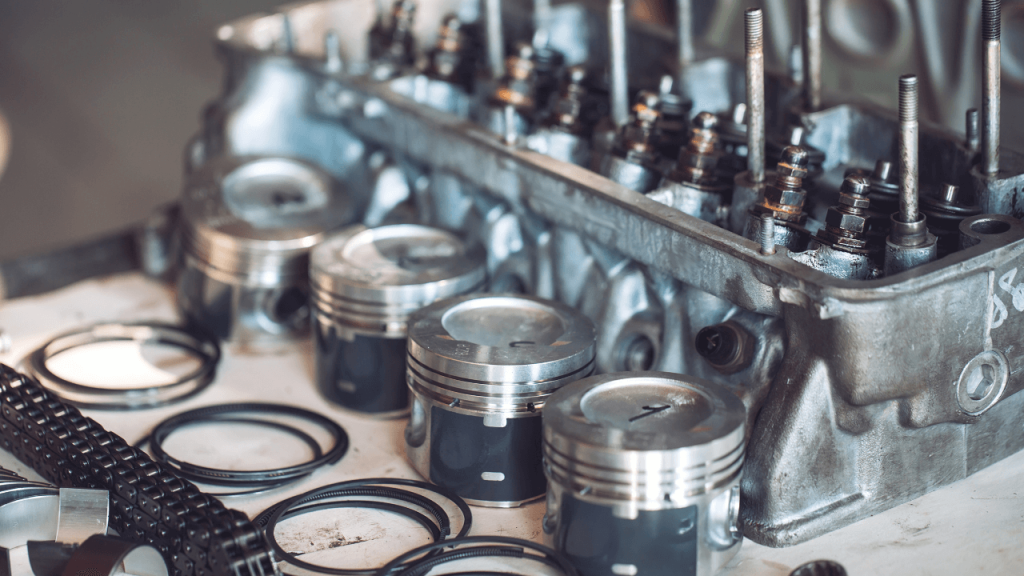

Engine rebuilding involves carefully dismantling, cleaning and inspecting all components, replacing or machining worn parts, and precise reassembly. Here are the key steps:

- Complete Disassembly: The engine is taken down to the block, with all internal parts removed. This exposes every component for inspection.

- Thorough Inspection: Each part is measured and tested for wear, damage or deviations from specifications. Blocks, heads and other surfaces are checked for flaws. This identifies all necessary repairs.

- Parts Replacement: Based on inspection findings, the engine builder replaces worn or damaged components with new OEM or performance parts. Typical new parts include pistons, rings, bearings, gaskets, oil pump, timing set, seals, and water pump.

- Machining and Refinishing: The block, heads, valves, and other surfaces are machined back to precise tolerances, making them like new again. Valve guides, valve seats and other components may also need machining or refinishing.

- Careful Assembly: The block is reassembled using torque specifications and proper clearances between components. Gaskets, seals and fittings are carefully installed to avoid leaks.

- Testing: The rebuilt engine is thoroughly tested on a dynamometer to verify performance and leak-free operation before delivery.

Benefits of Engine Rebuilding

- Cost Savings: Much less expensive than purchasing a remanufactured or new crate engine

- Reliability: New components fix existing problems to improve reliability

- Performance: Rebuilt to factory-new or better power and efficiency

- No Mileage: The engine has zero miles once rebuilt, extending its lifespan

- Customization: Can modify components to increase horsepower, torque, etc. during rebuild

- Warranty: Shops offer 1-3 year warranties on many engine components

Rebuilding is a smart investment to save thousands over engine replacement while restoring your vehicle’s health. Find a reputable shop with experienced engine builders to perform a professional rebuild.